Sterilization devices | Autoclaves

Laboklav ECO 80 and 135

DESIGNED FOR CHALLENGING INSTALLATION CONDITIONS AND POOR WATER QUALITY.

The Laboklav Eco series devices are characterized by user-friendliness and efficiency. They are designed for challenging installation conditions and poor water quality. The steam sterilizers are suitable for basic laboratory applications, offering maximum convenience at a low price. All necessary components are housed within the casing. Additionally, the devices provide various installation options. The lid can be opened to the left, right, or back. The units can also be operated and loaded from the narrow side, all without extra costs or effort. The compact design results in a low loading height, making it easier to load vertical autoclaves with baskets and bottles.

Laboklav ECO 80 and 135

Steam sterilization with chamber volumes of 80 or 135 liters

Both autoclaves, with 80 and 135-liter chamber volumes, offer optimal solutions for laboratories with varying sterilization needs. The 80-liter model, with a chamber diameter of ø 400 mm, is ideal for smaller batches, while the 135-liter model, with a chamber diameter of ø 500 mm, provides more capacity for larger or bulkier materials. Both versions combine spacious interiors with efficient performance, ensuring successful sterilization. They are perfect for labs that prioritize capacity and flexibility. At no additional cost, the units can be delivered in various color options. The casing panels are powder-coated in light gray for all color variants, while the visible part of the supporting frame is made of brushed stainless steel.

versatile

equipped for the sterilization of liquids, solids (no narrow hollow bodies), and easily vented waste

compact design

available in various color options

spacesaving

universally installable

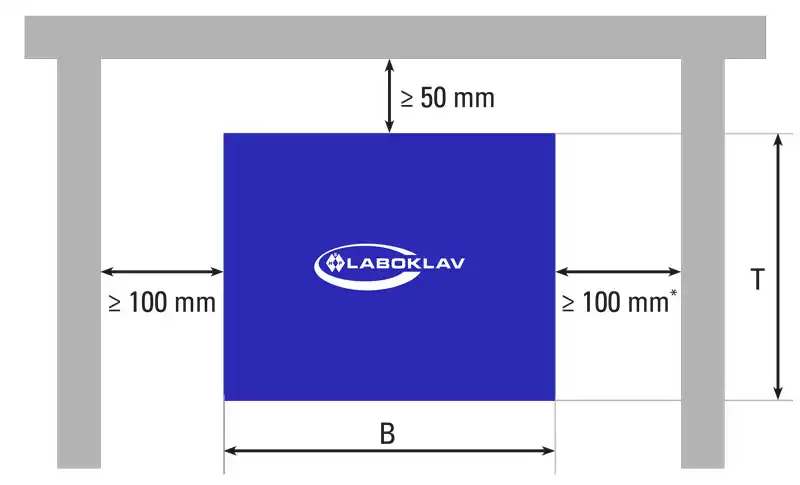

Dimensions for installing: (ECO 80)

B x H x D: 740 x 915 x 600 mm

Dimensions for installing: (ECO 135)

B x H x D: 840 x 965 x 700 mm

variable display orientation

configured as floor-standing unit

efficient & durable

heating elements located under the chamber floor

Power (ECO 80) 3 kW

Power (ECO 135) 6 kW

heating elements are not submerged in water (thereby extending their lifespan)

excellent

True 32-bit system with large multicolor touch control panel and internal 16 GB memory

- High loading volume

- Low electricity costs

The assumption that a large chamber automatically means a high loading capacity is widespread. However, especially when loading with liquids in 1-liter bottles, this is not always accurate. The more compact the device, the more expensive stainless steel is saved, and less heating power is required to bring the sterilization goods to the required temperature. During the cooling phase, only the energy that was previously introduced needs to be removed. The device is equipped with heating power that is optimally matched to the chamber size and processes. This adjustment of heating power leads to significant savings in operating costs and faster processes.

Product features and technical specifications

Sterilization chamber

Direct steam heating through heating elements at the chamber base

Lid and Closure

Hinged lid with motorised closure, safety locking mechanism

Lid seal

T-profile seal, silicone

Temperature measurement technology

Independent PT100 sensors with a response time T0.9 = 3 s,

2-wire technology, internal resolution 0.01K, display resolution 0.1K,

calibratable, Monitoring of sensor breakage and sensor short circuit

Reference sensor for liquids

Sensor as described in temperature measurement technology with flexible measuring cable, standard in all types

Calibration certificate according to ISO

inclusive across all devices

Pressure measurement technology

Electronic pressure sensor 0 to 6 bar, absolute or relative pressure measurement, programmable, monitoring of sensor break, resolution/display 0.1 kPa

Calibration certificate according to ISO

inclusive across all devices

Feed water supply

Manual filling, directly into the chamber

Overtemperature protection for heating

Overtemperature protection by separate overtemperature protection switch, 1x with autoreset

Sterilization ventilation

Membrane filter, µ ≤ 0.2 µm, included as standard in all models

Display of service intervals

Automatic notification via multicolor display

Microprocessor control

Control of all functions, display via multicolor display

For heating and chamber pressure monitoring

Timer

Program start programmable by date and time

Audible signal

Can be activated

Interfaces

Internal RS232 for printer

External USB for printer, network, computer connection

Sterilization programs

5 predefined programs in level 1:

The program allocation is based on the configuration levels. The programs can be individually modified.

5 programs in level 2:

Programs P6 to P10 Code protected, pre-set like P1

CUSTOMER SERVICE is a top priority for us.

Our service network ensures short response times and competent service technicians with many years of experience in steam sterilization. Our fair prices and the service-friendly design of our devices keep costs low. We take care of your equipment.

Optional for the Laboklav ECO 80 and 135

Option M: Fast recooling

(without counter pressure, for open vessels)

The Laboklav ECO series can optionally be equipped with a highly effective rapid cooling system for liquids. A powerful fan circulates cold ambient air around the chamber during the cooling phase, accelerating the cooling of liquids. As a result, the cooling phase can be reduced by up to 50%*.

* Depending on bottle size and load volume

exhaust air filtration – to protect the user and the environment

The exhaust air filtration meets the requirements of the Biostoffverordnung (BioStoffV), including TRBA 100, as well as the Genetic Engineering Safety Regulation (GenTSV) in terms of structure and function. The device is therefore suitable for use in areas with protection/security level 2 or higher. The exhaust air filtration includes the sterilization of the condensate and the temperature-controlled decontamination of the filter candle in each cycle. A PT100 temperature sensor integrated into the filter housing ensures successful sterilization.

The filter housing is easily accessible to the user, integrated into the unit, and accessible when the lid is open. A pressure-tight stainless steel housing encloses the plastic-coated hydrophobic filter element with a mesh size of 0.2 μm.

The batch counter integrated into the control system allows monitoring of the filter element's lifespan and provides information on when a filter replacement is necessary.

SegoSoft

SegoSoft - the fully automated, digital batch and process documentation for your sterilizers, thermal disinfectors, and sealing devices.

cladding sheets and cover hood in stainless steel

The stainless steel cover hood ensures a safe, hygienic seal and is easy to clean. The stainless steel cladding sheets are robust and durable.

The individual options are based on the current state of technology and the requirements of applicable laws, regulations, standards, and directives, including:

ArbSchutzG: Arbeitsschutzgesetz

ÜAnlG: Gesetz über überwachungsbedürftige Anlagen

BetrSichV: Betriebssicherheitsverordnung

DIN 58951-2:2018-01: Sterilization - Steam sterilizers for laboratory sterilization items - Part 2

DIN EN 61010-1 VDE 0411-1:2020-03: Safety requirements for ... laboratory equipment

Richtlinie 2014/68/EU: Pressure Equipment Directive

TRB 402: Equipment of pressure vessels, openings, and closures

TRBA 100: Protective measures for activities involving biological agents

GenTSV: Genetic Engineering Safety Ordinance

DE

DE  EN

EN  PL

PL  FR

FR  ES

ES  SV

SV  NL

NL  AR

AR